About us

Hotline:+86-186-8100-4097

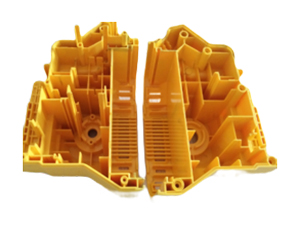

Power tool housings are mainly composed of three materials, aluminum or plastic or iron,

Common faults and solutions of power tool casings

1, broken, generally need to be replaced, can be repaired with a plastic welding torch when the machine cannot be purchased outside

2, the bearing is worn out, and it generally needs to be replaced with a new one. If it is not available, it can be tinned on the outer ring of the bearing

3. Deformation makes the stator and rotor swept, and a piece of paper can be sandwiched between the stator and the casing to adjust the position of the stator so that the rotor and the stator are not swept.

Three, replacement method and precautions

1. The electric drill uses two plastic shells to clamp the iron core rotor type. The fixing screws cannot be missing, otherwise the stator and rotor will be swept. If the bolts cannot be tightened, you can use longer or thinner screws. Solve

2. The quality of the assembly is very important.

3. Some plastic shell bearing chambers are embedded with iron bearing sleeves. When taking out the broken bearings, be careful to avoid removing them

4. For the plastic casing of the electric drill, if the sliding wire of the casing fixing screw is not tightened, there may be a malfunction of the sweep. The solution is to use a longer screw or a thicker screw to strengthen it, or you can use the long screw Saw it short for use,

5. When the bearing of a power tool with a plastic casing is locked, it is likely to cause the plastic casing to overheat and melt and become unusable, or cracks may occur, resulting in unusable use.

Copyright © 2022 Dongguan Huasheng Precision Mould Co., Ltd. All rights reserved【Baidu Statistics】【Admin】【Back to top】

Hotline

Mr. Liu

Mobile